THE MAAS+ROOS

360° SUSTAINABILITY

APPROACH

If you watch this video, you agree to our privacy policy.

Sustainability has always been a high priority at MAAS+ROOS

and it is part of our corporate culture. We see it as our entrepreneurial duty

to protect our resources and the environment.

We do not primarily focus on the trading of emissions. Instead, we lower our emissions

and use of raw materials in production and logistics.

We complete this approach by recycling everything from aluminium and steel to

packaging materials like cardboard and plastic wrapping.

Production

State-of-the-art production facilities

Solvent free powders and waterbased paints

Certification: ISO 9001 and ISO 14001

Logistics

Co2 savings through production closer to the customer – in Germany, Dubai and India

CO2 savings through optimized logistics routes and group transports

Reduction of packaging materials through

delivery to many markets with own means of transport

Recycling

We separate over 25 materials and return

them into the circulation

Fine-particle dust extraction throughout

entire production area

ISO 14001 certification underlines a

comprehensive environmental policy

Production

State-of-the-art production facilities

Solvent free powders and waterbased paints

Certification: ISO 9001 and ISO 14001

Logistics

Co2 savings through production closer to the customer – in Germany, Dubai and India

CO2 savings through optimized logistics routes and group transports

Reduction of packaging materials through

delivery to many markets with own means of transport

Recycling

We separate over 25 materials and return

them into the circulation

Fine-particle dust extraction throughout

entire production area

ISO 14001 certification underlines a

comprehensive environmental policy

FULLY RECYCLABLE

AND SUBSTAINABLE

GREENFLEX is a brand new illuminated sign system.

Developed with sustainability in mind it is the first product of

its kind and fits perfectly within the Maas+Roos 360° sustainability

framework.

Made from up to 80% renewable material the sign can be disassembled into individual components and recycled at the end of its life cycle!

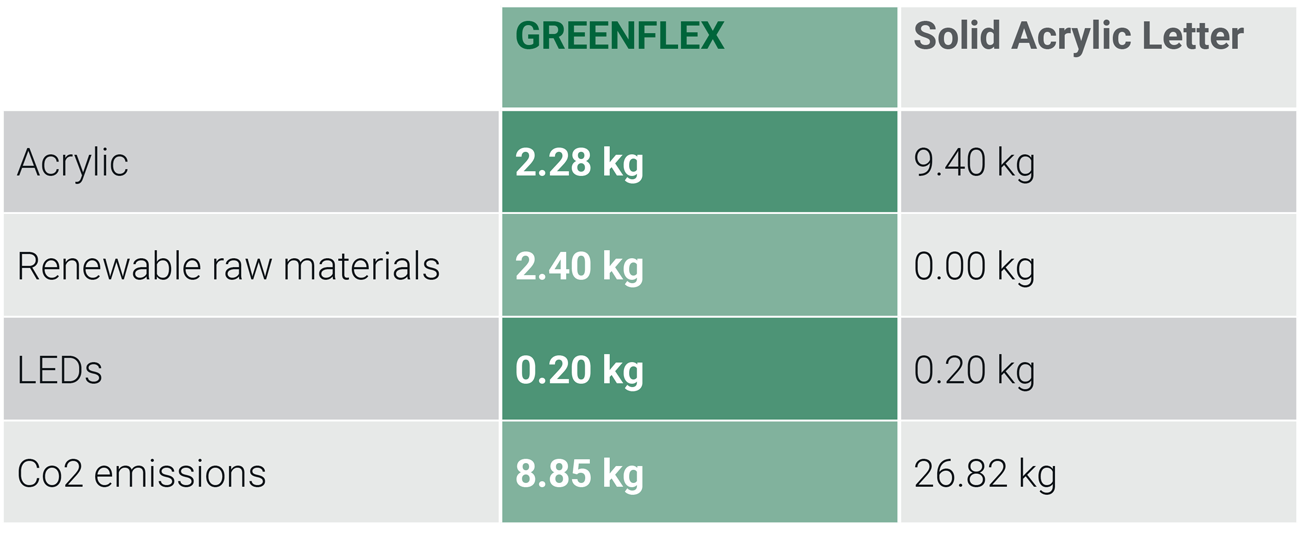

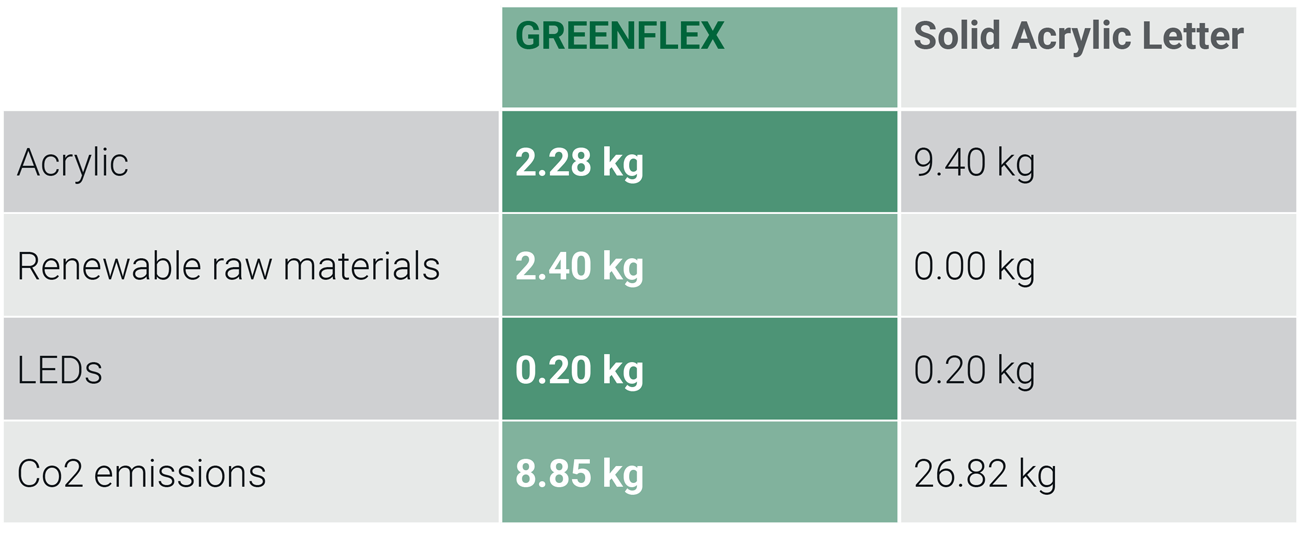

COMPARISON CALCULATION

How much Co2 does GREENFLEX save

compared to typical solid acrylic letters?

FULLY RECYCLABLE

AND SUBSTAINABLE

GREENFLEX is a brand new illuminated sign system.

Developed with sustainability in mind it is the first product of

its kind and fits perfectly within the Maas+Roos 360° sustainability

framework.

Made from up to 80% renewable material the sign can be disassembled into individual components and recycled at the end of its life cycle!

COMPARISON CALCULATION

How much Co2 does GREENFLEX save

compared to typical solid acrylic letters?

ILLUMINATED WOOD LETTERS

Up to 80% produced from renewable

raw materials

The wooden material used is made from

already recycled wood

Acrylic used can optionally be designed

with a closed product life cycle

ILLUMINATED WOOD LETTERS

Up to 80% produced from renewable

raw materials

The wooden material used is made from

already recycled wood

Acrylic used can optionally be designed

with a closed product life cycle

GREENFLEX is the first fully recyclable illuminated sign system on

the market. If desired, the minimum acrylic content

required can also be produced in a closed product life cycle.

Powder Coating

35% less Co2 emissions

through sustainable

powder coating!

Maas+Roos saves 12.8 tons of Co2 per year through innovative powder coating

Powder coating has a number of advantages compared to conventional painting, including being significantly more sustainable – we save a lot of CO2 as a result.

To be precise, it is approx. 12.8 tons per year, which corresponds to a saving of approx. 32,000 kilowatt hours of unused energy!

In addition, waste water is treated and not discharged into the sewage system.

![]()

Co2 savings of 35%:

– 12.8 tons of Co2/year

– 32,000 KwH/year

Powder Coating

35% less Co2 emissions

through sustainable

powder coating!

Maas+Roos saves 12.8 tons of Co2 per year through innovative powder coating

Powder coating has a number of advantages compared to conventional painting, including being significantly more sustainable – we save a lot of CO2 as a result.

To be precise, it is approx. 12.8 tons per year, which corresponds to a saving of approx. 32,000 kilowatt hours of unused energy!

In addition, waste water is treated and not discharged into the sewage system.

![]()

Fresh water saving

of 450.000 liters

Water Treatment Plant

450,000 LITERS

FRESH WATER

SAVED:

WASTE WATER

BECOMES PREPARED

AND REUSED!

Maas+Roos saves annually up to

450,000 liters fresh water

An in-house water treatment plant clears and filters waste

water and prepares it so that it can be used again for the

production process.

Water Treatment Plant

450,000 LITERS

FRESH WATER

SAVED:

WASTE WATER

BECOMES PREPARED

AND REUSED!

Maas+Roos saves annually up to

450,000 liters fresh water

An in-house water treatment plant clears and filters waste

water and prepares it so that it can be used again for the

production process.

RECYCLED ACRYLIC

RECYCLED ACRYLIC

REDUCES CO2

EMISSIONS BY 76%!

On request, we can produce your illuminated advertising system from 100% recycled acrylic – and of course with the well-known advantages of a Maas-Roos advertising system.

RECYCLED ACRYLIC

RECYCLED ACRYLIC

REDUCES CO2

EMISSIONS BY 76%!

On request, we can produce your illuminated advertising system from 100% recycled acrylic – and of course with the well-known advantages of a Maas-Roos advertising system.

![]()

52% more light output

LATEST LED-TECHNOLOGY

52% MORE

LIGHT EFFICIENCY

AT THE SAME

ENERGY CONSUMPTION!

Depending on the configuration and order, we install the latest LED technology and thus bring up to 52% more light output into your advertising system with the same energy consumption.

This significantly increases efficiency and thereby saves energy costs and Co2 emissions.

LATEST LED-TECHNOLOGY

52% MORE

LIGHT EFFICIENCY

AT THE SAME

ENERGY CONSUMPTION!

Depending on the configuration and order, we install the latest LED technology and thus bring up to 52% more light output into your advertising system with the same energy consumption.

This significantly increases efficiency and thereby saves energy costs and Co2 emissions.

Recycling

RECYCLING FROM

PRODUCTION

WASTE!

We recycle over 25 materials that are required in the production process – each individual component is professionally disposed of and thus fed back into the material cycle.

Take-back

TAKE-BACK AND

RECYCLING OF

ADVERTISING EQUIPMENT.

On request, we will take back dismantled systems, dismantle them and feed them into the material cycle via our recycling process – for a clean environment and maximum sustainability.

![]()

recycling of over

25 materials!

Recycling

52% MORE

RECYCLING FROM

PRODUCTION WASTE!

We recycle over 25 materials that are required in the production process – each individual component is professionally disposed of and thus fed back into the material cycle.

Take-back

TAKE-BACK AND

RECYCLING OF

ADVERTISING EQUIPMENT.

On request, we will take back dismantled systems, dismantle them and feed them into the material cycle via our recycling process – for a clean environment and maximum sustainability.

LOGISTICS

SMART

LOGISTICS FOR

MAXIMUM

SUSTAINABILITY

Co2 savings through customer-oriented production – in Germany and in the partner network in Dubai, India and the USA.

Co2 savings through optimized logistics routes and group transport as well as reduction of packaging material through intelligent packaging solutions.

![]()

Sustainability

through intelligent

logistics solutions.

E‑Mobility

CONVERSION

CORPORATE FLEET

ON E‑MOBILITY

Our company fleet will be converted to e‑cars as needed – this is how we reduce Co2 emissions where it makes sense and is economical.

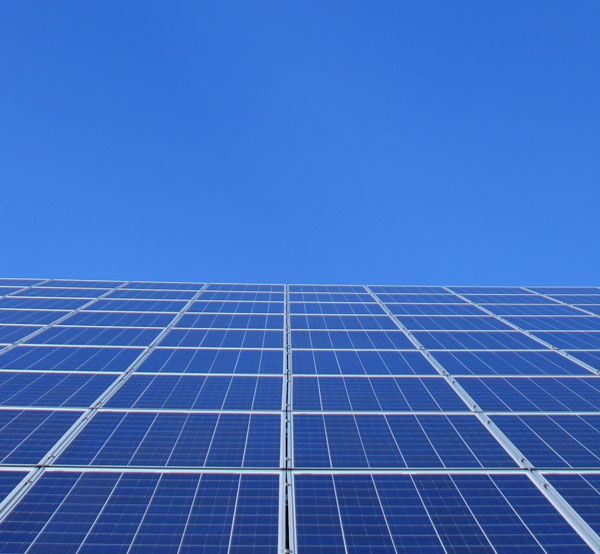

Solar Energy

OWN

PRODUCTION OF

GREEN ENERGY!

In the near future we will be equipping our production buildings with solar elements – this will enable us to produce up to 630,000 kWh of green electricity per year on a roof area of over 6,000 square meters!

This makes us up to 43% self-sufficient from external energy suppliers and saves up to 252 tons of Co2 emissions/year.

![]()

Own production of green

electricity: 630.00 Kwh/year

Saving of 252 tons of

Co2 emissions/year.

LOGISTICS

SMART

LOGISTICS FOR

MAXIMUM

SUSTAINABILITY

Co2 savings through customer-oriented production – in Germany and in the partner network in Dubai, India and the USA.

Co2 savings through optimized logistics routes and group transport as well as reduction of packaging material through intelligent packaging solutions.

E‑Mobility

CONVERSION

CORPORATE FLEET

ON E‑MOBILITY

Our company fleet will be converted to e‑cars as needed – this is how we reduce Co2 emissions where it makes sense and is economical.

Solar Energy

OWN

PRODUCTION OF

GREEN ENERGY!

In the near future we will be equipping our production buildings with solar elements – this will enable us to produce up to 630,000 kWh of green electricity per year on a roof area of over 6,000 square meters!

This makes us up to 43% self-sufficient from external energy suppliers and saves up to 252 tons of Co2 emissions/year.